Preface

A note from the author: “This is another one of my academic papers from a few years ago and follows on from this case study about sustainability goals. It explores how the Rheinmetall Group, a multinational automotive and defence company, navigates its journey towards sustainability. By integrating the principles of Design for Sustainability, the research delves into the importance of indigenous knowledge and gender diversity in achieving the United Nations’ Sustainable Development Goals (SDGs). Through critically evaluating Rheinmetall’s strategies, the paper highlights the challenges and opportunities in building a more inclusive and sustainable future.

This paper differs from our other blog articles due to its more formal language. If you’re not interested in academic writing or looking for particular sustainability information, it’s probably not for you. You’ll note that it has a list of references at the end for those looking for more information. I welcome your comments and questions, especially if one of the linked resources is no longer available.” – Ewan Williams, October 2024.

Table of Contents

Introduction

Rheinmetall Group (RG) were founded in 1889 and have grown to become an integrated technology company who are also one of the most eminent suppliers and innovators, to and in, the global defence and automotive industries.

With 198 interconnected companies across these sectors, a physical footprint in 33 countries, and operations in 137 more, RG is uniquely positioned to enact a corporate strategy that more succinctly addresses the world’s sustainability challenges. With a heavy research and development focus and by leveraging its expertise to develop innovative solutions, RG can contribute to a safe and liveable future for all.

As a company that at its core is a product design, engineering and manufacturing powerhouse, this paper will put forward a vision for strategic change, where current practices are reimagined utilising a sustainability mindset. Current shortcomings, a strategy for incorporating a Design For Sustainability (DFS) approach that considers associated challenges, pros and cons will be presented. Alongside this, one will define a series of directives RG could enact to ensure successful outcomes by 2032.

The 2030 Agenda & Rheinmetall Group

The size and breadth of RG mean it has long had sustainability at the core of its business (Rheinmetall Aktiengesellschaft, 2021). However, there are some clear shortcomings related to the 2030 Agenda for Sustainable Development (The 2030 Agenda; United Nations, 2015).

Firstly, the lack of First Peoples perspectives, whereby the pursuit of homogeneity of views and priorities effectively silences indigenous perspectives (Yap & Watene, 2019; Watene & Yap, 2015; Carling et al., 2017) and oftentimes leaves them marginalised economically and socially (O’Faircheallaigh, 2013). This is counterproductive when we consider the positive outcomes influenced by these views (Magni, 2017; Warren et al., 1993; Agrawal, 1995; Agrawal, 2002).

Secondly, the decreasing number of women in the organisation and the overall low participation rate compared to other industries are causes for concern. Only 21% of employees are female, and fewer still are in management roles below the Executive Board when considering the top four levels (10.4%; Rheinmetall Aktiengesellschaft, 2021). Research suggests that automotive companies with women on their boards perform better (Horak & Cui, 2017), while company culture and a lack of acceptance and inclusion drive women away (Bullock, 2019; Deloitte Development LLC, 2020).

Lastly, with a disjointed and complex supply chain that has questionable transparency, RG must contend with the challenges of ensuring environmental and human rights due diligence throughout. With more than 40,000 suppliers worldwide, this is an onerous task at the best of times. However, acting as a sustainability champion can contribute to the adoption of a similar focus from upstream and downstream suppliers in both a direct and indirect manner, driving positive outcomes (Seles et al., 2016; Wolff et al., 2020).

The Future Vision

RG has the reach, influence and stakeholder engagement that uniquely position them to implement a strategy that can have far-reaching ramifications the world over. While they are working toward clearly defined strategies that address various Sustainable Development Goals (SDGs), including building resilient infrastructure, promoting inclusive and sustainable industrialization, fostering innovation, diversity and inclusion, environmental protection, etc. (Rheinmetall Aktiengesellschaft, 2021), this does not directly address sustainability from a product design perspective.

So, the question remains: As a designer, engineer, and manufacturer of complex systems, how can RG change its product design to incorporate sustainability at its core? In other words, how can its vehicles, used by civilians and militaries around the world, oftentimes in the most inhospitable and insecure environments, that have precise customer requirements, continue to meet those demands while incorporating sustainability goals on an equal footing?

For RG to truly adopt a sustainability mindset, the organisation needs to start with the design of its products. Over the years there have been more than 75 different approaches for the ‘Design For X’ paradigm described in academic literature and a large array of tools that help integrate sustainability considerations into the process of new product design (Benabdellah et al., 2019; Benoit et al., 2010; Wu et al., 2014; Hebrok, 2014; Hagman et al., 2016; Rusich & Danielis, 2015; Mayyas et al., 2012; Schmidt & Taylor, 2006; Byggeth & Hochschorner, 2006; Maxwell & van der Vorst, 2003; Romli et al., 2014; Byggeth et al, 2007; Howarth & Hadfield, 2006).

Unfortunately, most of these tools only consider the environmental aspects of sustainability and do not consider the social aspect (Schoggl et al., 2017). By focusing on the idea of Design For Sustainability (DFS; Figure 1) and incorporating the Checklist for Sustainable Product Development (CSPD; Schoggl et al., 2017) into their internal product development processes, RG will effectively consider sustainability on an equal footing with customer requirements and be making excellent inroads toward The 2030 Agenda.

Figure 1 – Visual representation of the Design For Sustainability (DFS) concept conveyed in Jawahir et al. (2007).

To digress, the vision of integrating sustainability as a key consideration when designing a new product requires diverse viewpoints and unconventional thinking. This is a contributing reason why the previously discussed topics of First Peoples perspectives and the declining number of women within RG’s business are of paramount concern.

Primary Challenges, Pros & Cons

Implementing a DFS approach is not without its challenges. Firstly, designers and engineers are not typically trained to consider sustainability outcomes when designing new products; hence, there is a need for effective tools such as the CSPD to help guide their considerations.

There are also concerns that quantifying environmental and social aspects, especially with innovative and new technologies, is difficult due to a general lack of actionable information (Ny et al., 2006). Others imply that having designers and engineers exposed to this level of information can suppress creativity and contribute to negative sustainability outcomes (Collado-Ruiz & Ostad-Ahmad-Ghorabi, 2010).

Research also suggests that Sustainable Product Design (SPD) critically relies on inter-functional collaboration (De Medeiros et al., 2014). The CSPD tool itself may require customisation (Petala et al., 2010; Schoggl et al., 2017) to fit within RG’s existing processes. This will ensure it remains specific enough to deliver the desired outcomes but broad enough to consider that key stakeholders involved in product development may come from various disciplines, including engineering, logistics, production, supply chain, HR and others (Schoggl et al., 2017; Berchicci & Bodewes, 2005).

Additionally, designers and engineers will require optimal support for successful implementation and utilisation (Bocken et al., 2014), and RG should consider using an “SDG Owner” (Wolff et al., 2020) to guide these processes. This will help negate simple failures and misunderstandings while bridging the divide between strategy and implementation for the interdepartmental teams that are common in the automotive and defence industries.

RG will also need to consider that vehicle designs are usually iterations of previous designs. As a result, it will be critical to review each sub-component with fresh eyes when conducting ‘new’ product design processes. Given the volume of parts sourced from third parties, this is a significant challenge in its own right.

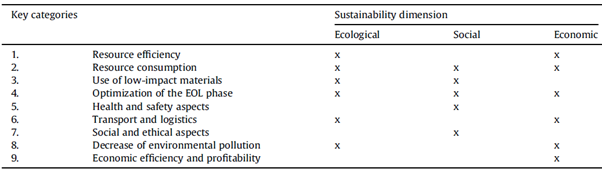

That aside, the CSPD itself is well designed, with a specific focus on the automotive industry. The questions have been designed to cover nine key categories across the three tiers of sustainability: ecological, social, and economic (Table 1).

Table 1 – Adapted from Schoggl et al. (2017).

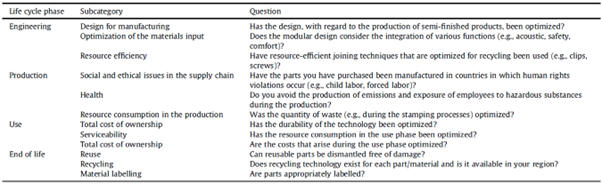

The CSPD also ensures consideration across the various life cycle phases and in keeping with simplicity, the questions it asks throughout are binary in nature (Table 2). This approach ensures that the tool is used to promote a discussion, as opposed to driving things in a particular direction.

Table 2 – Example questions from the CSPD (Schoggl et al., 2017)

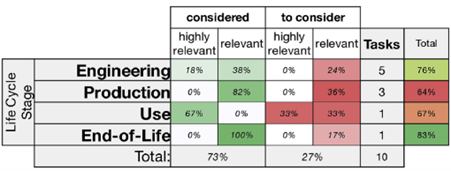

Importantly, the CSPD generates a “Task List” and “Evaluation Sheet” that makes it easier for those involved in product development to keep track of actions across multiple meetings/iterations (Schoggl et al., 2017) along with visual cues as to what has/has not been considered (Figure 2).

Figure 2 – Example evaluation sheet (Schoggl et al., 2017)

Conclusion & Directives Towards ‘Design For Sustainability’

With operations across ~70% of nation-states on the planet, RG can effect significant change in the world. The directives outlined in Table 3 below will allow for a change in perspective to put sustainability and customer requirements on an even keel and achieve a Design For Sustainability approach across the business.

| Directive 1.0 | During X year, conduct an initial assessment via an anonymous survey of organisational culture in light of challenges around diversity and inclusion. From then on, conduct this assessment every 2 years and implement strategies to increase engagement levels across the business after analysing each result. Performance Measures: Survey results, increasing engagement scores. |

| Directive 2.0 | By X year, adopt a DFS approach for the civilian vehicle market that includes customising and implementing the CSPD. Performance Measures: Number of staff trained in DFS and the use of integrated CSPD, use of and sign-off by management of CSPD to ensure utilisation. |

| Directive 2.1 | Work with internal and external key stakeholders to customise the CSPD and implement it before the end of X year. |

| Directive 2.2 | By X year, internal governance will be modified to ensure DFS becomes the defining design and engineering principle. |

| Directive 2.3 | By X year, ensure all stakeholders involved in product development are trained in the DFS approach and the now-integrated CSPD. |

| Directive 3.0 | By X year, adopt a DFS approach for the military vehicle market, including the customised and implemented CSPD. Performance Measures: Number of staff trained in DFS and the use of integrated CSPD, use of and sign-off by management of CSPD to ensure utilisation. |

| Directive 4.0 | By X year, extend use of the CSPD to 100% of companies in the supply chain and hold suppliers to the same standard, utilising modified Supplier Code of Conduct agreements. Performance Measures: Number of suppliers who have implemented a DFS approach and the CSPD tool, number of suppliers who have signed the modified Supplier Code of Conduct. |

| Directive 4.1 | Assuming 2.1 is finalised by the end of X year, grow use of the CSPD by at least 11.12% every year to ensure timelines are met. The initial focus should be on the most significant suppliers (volume or dollars) before moving to smaller suppliers. |

Understanding that RG products have lengthy lifecycles, it is not possible to adapt overnight. With the next generation of vehicles, both civilian and military, well into their manufacturing ramp-up, the above outlines a staggered approach over the next 10 years that will move RG to a more sustainability-focused future.

RG’s position in the market affords it great power and influence, especially as it relates to their extensive supplier network. By acting as a sustainability leader and putting these considerations at the core of their actions, RG can also exert pressure throughout their self-purported fragmented and complex supply chain (Rheinmetall Aktiengesellschaft, 2021). This direct and indirect pressure has been found to influence the adoption of green supply chain management practices (Seles et al., 2016; Williams, 2021).

References

While all links worked at the time of publication, please leave a comment where resources are no longer accessible.

- Agrawal, A. (1995). Dismantling the divide between indigenous and scientific knowledge. Development and Change, 26, 413–439. https://doi.org/10.1111/j.1467-7660.1995.tb00560.x

- Agrawal, A. (2002). Indigenous knowledge and the politics of classification. International Social Science Journal, 54, 287–297. https://onlinelibrary.wiley.com/doi/pdfdirect/10.1111/1468-2451.00382

- Benabdellah, A. C., Bouhaddou, I., Benghabrit, A., & Benghabrit, O. (2019). A systematic review of design for X techniques from 1980 to 2018: concepts, applications, and perspectives. The International Journal of Advanced Manufacturing Technology, 102, 3473–3502. https://doi.org/10.1007/s00170-019-03418-6

- Benoit, C., Norris, G.A., Valdivia, S., Ciroth, A., Moberg, A., Bos, U., Prakash, S., Ugaya, C., & Beck, T. (2010). The guidelines for social life cycle assessment of products: just in time! International Journal of Life Cycle Assessment, 15, 156-163. https://doi.org/10.1007/s11367-009-0147-8

- Berchicci, L., & Bodewes, W. (2005). Bridging environmental issues with new product development. Business Strategy and the Environment, 14, 272-285. https://doi.org/10.1002/bse.488

- Bocken, N. M. P., Farracho, M., Bosworth, R., & Kemp, R. (2014). The front-end of ecoinnovation for eco-innovative small and medium sized companies. Journal of Engineering and Technology Management, 31, 43-57. https://doi.org/10.1016/j.jengtecman.2013.10.004

- Bullock, C. L. (2019). Driving new narratives: Women-leader identities in the automotive industry. Gender in Management: An International Journal, 34(3), 200-216. https://doi.org/10.1108/GM-10-2017-0135

- Byggeth, S., & Hochschorner, E. (2006). Handling trade-offs in Ecodesign tools for sustainable product development and procurement. Journal of Cleaner Production, 14, 1420-1431. https://doi.org/10.1016/j.jclepro.2005.03.024

- Byggeth, S., Broman, G., & Robert, K.H. (2007). A method for sustainable product development based on a modular system of guiding questions. Journal of Cleaner Production, 15, 1-11. https://doi.org/10.1016/j.jclepro.2006.02.007

- Carling, J., Ibrahim, H., & Oelz, M. (2017). ‘Development Makes Us Vulnerable’: Call for SDGs to Learn From Indigenous Peoples. Retrieved 15 November 2021 from https://europa.eu/capacity4dev/articles/development-makes-us-vulnerable-call-sdgs-learn-indigenous-peoples

- Collado-Ruiz, D., & Ostad-Ahmad-Ghorabi, H. (2010). Influence of environmental information on creativity. Design Studies, 31, 479-498. https://doi.org/10.1016/j.destud.2010.06.005

- De Medeiros, J. F., Ribeiro, J. L. D., & Cortimiglia, M. N. (2014). Success factors for environmentally sustainable product innovation: A systematic literature review. Journal of Cleaner Production, 65, 76-86. https://doi.org/10.1016/j.jclepro.2013.08.035

- Deloitte Development LLC. (2020). Women at the wheel: Key findings from the 2020 Diversity, Equity, and Inclusion in Automotive Study. https://www2.deloitte.com/us/en/pages/manufacturing/articles/diversity-women-in-the-automotive-industry.html

- Hagman, J., Ritzen, S., Stier, J. J., & Susilo, Y. (2016). Total cost of ownership and itspotential implications for battery electric vehicle diffusion. Research in Transportation Business & Management, 18, 11-17. https://doi.org/10.1016/j.rtbm.2016.01.003

- Hebrok, M. (2014). Design for longevity: taking both the material and social aspects of product-life into account. Journal of Design Research, 12(3), 204-220. https://doi.org/10.1504/JDR.2014.064232

- Horak, S., & Cui, J. (2017). Financial performance and risk behavior of gender-diversified boards in the Chinese automotive industry. Personnel Review, 46(4), 847-866. https://doi.org/10.1108/PR-10-2015-0274

- Howarth, G., & Hadfield, M. (2006). A sustainable product design model. Materials & Design, 27, 1128-1133. https://doi.org/10.1016/j.matdes.2005.03.016

- Jawahir, I. S., Rouch, K. E., Dillon, O. W., Holloway, Jr. L., & Hall, A. (2007). Design for sustainability (DFS): new challenges in developing and implementing a curriculum for next generation design and manufacturing engineers. International Journal of Engineering Education, 23(6), 1053–1064. https://www.ijee.ie/articles/Vol23-6/s3_ijee1999.pdf

- Magni, G. (2017). Indigenous knowledge and implications for the sustainable development agenda. European Journal of Education, 52, 437-447. https://doi.org/10.1111/ejed.12238

- Maxwell, D., & van der Vorst, R. (2003). Developing sustainable products and services. Journal of Cleaner Production, 11, 883-895. https://doi.org/10.1016/S0959-6526(02)00164-6

- Mayyas, A., Qattawi, A., Omar, M., & Shan, D. (2012). Design for sustainability in automotive industry: a comprehensive review. Renewable and Sustainable Energy Reviews, 16(4), 1845-1862. https://doi.org/10.1016/j.rser.2012.01.012

- Ny, H., Macdonald, J. P., Broman, G., Yamamoto, R., & Robert, K-H. (2006). Sustainability constraints as system boundaries – an approach to making life-cycle management strategic. Journal of Industrial Ecology, 10, 61-77. https://doi.org/10.1162/108819806775545349

- O’Faircheallaigh, C. (2013). Extractive industries and Indigenous peoples: A changing dynamic? Journal of Rural Studies, 30, 20-30. https://doi.org/10.1016/j.jrurstud.2012.11.003

- Petala, E., Wever, R., Dutilh, C., & Brezet, H. (2010). The role of new product development briefs in implementing sustainability: a case study. Journal of Engineering and Technology Management, 27, 172-182. https://doi.org/10.1016/j.jengtecman.2010.06.004

- Rheinmetall Aktiengesellschaft. (2021). Annual Report 2020. https://ir.rheinmetall.com/download/companies/rheinmetall/Annual%20Reports/DE0007030009-JA-2020-EQ-E-00.pdf

- Romli, A., Prickett, P., Setchi, R., & Soe, S. (2014). Integrated eco-design decision-making for sustainable product development. International Journal of Production Research, 53(2), 549-571. https://doi.org/10.1080/00207543.2014.958593

- Rusich, A., & Danielis, R. (2015). Total cost of ownership, social lifecycle cost and energy consumption of various automotive technologies in Italy. Research in Transportation Economics, 50, 3-16. https://doi.org/10.1016/j.retrec.2015.06.002

- Schmidt, W-P., & Taylor, A. (2006). Ford of Europe’s product sustainability index [Keynote presentation]. 13th CIRP International Conference on Life Cycle Engineering, Belgium. https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=26f932459afc9c5c786d95587ac617d063cde1ec

- Schöggl, J-P., Baumgartner, R. J., & Hofer, D. (2017). Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. Journal of Cleaner Production, 140(3), 1602-1617. https://doi.org/10.1016/j.jclepro.2016.09.195

- Seles, B. M. R. P., de Sousa Jabbour, A. B. L., Jabbour, C. J. C., & Dangelico, R. M. (2016). The green bullwhip effect, the diffusion of green supply chain practices, and institutional pressures: Evidence from the automotive sector. International Journal of Production Economics, 182, 342-355. https://doi.org/10.1016/j.ijpe.2016.08.033

- United Nations General Assembly. (2015). Transforming Our World: the 2030 Agenda for Sustainable Development. https://www.unfpa.org/sites/default/files/resource-pdf/Resolution_A_RES_70_1_EN.pdf.

- Warren, D. M., von Liebenstein, G. W., & Silkkerveer, L. (1993). Networking for indigenous knowledge. Indigenous Knowledge and Development Monitor, 1, 2–4. https://cir.nii.ac.jp/crid/1572261549618991232

- Watene, K., & Yap, M. (2015) Culture and Sustainable Development: Indigenous Contributions. Journal of Global Ethics, 11(1), 51-55. https://doi.org/10.1080/17449626.2015.1010099

- Williams, E. R. (2021). Case Study – Sustainability Goals, and Effects on an Automotive & Defence Company [Unpublished manuscript]. Griffith University, Queensland. https://refractedaspect.com/case-study-sustainability-goals-and-effects-on-an-automotive-defence-company/

- Wolff, S., Bronner, M., Held, M. & Lienkamp, M. (2020). Transforming automotive companies into sustainability leaders: A concept for managing current challenges. Journal of Cleaner Production, 276. https://doi.org/10.1016/j.jclepro.2020.124179

- Wu, R., Yang, D., & Chen, J. (2014). Social life cycle assessment revisited. Sustainability, 6(7), 4200-4226. https://doi.org/10.3390/su6074200

- Yap, M. L., & Watene, K. (2019) The Sustainable Development Goals (SDGs) and Indigenous Peoples: Another Missed Opportunity?, Journal of Human Development and Capabilities, 20(4), 451-467. https://doi.org/10.1080/19452829.2019.1574725